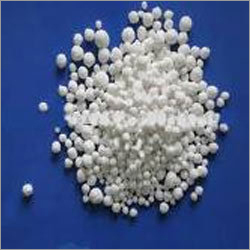

Magnesium Stearate

Magnesium Stearate Specification

- Shelf Life

- 12 Months

- Storage

- Room Temperature

- Solubility

- In Water

- Medicine Name

- Magnesium Stearate

- Chemical Name

- Magnesium Stearate

- Grade

- Industrial Grade

- Purity(%)

- 99%

- Physical Form

- Granular

Magnesium Stearate Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 7 Days

About Magnesium Stearate

We are the one of notable manufacturers, exporters and supplier of high quality Magnesium Stearate. This chemical is processed under the supervision of our experts using quality tested basic chemicals. Contains two equivalents of stearate (the anion of stearic acid) and one magnesium cation, this chemical is often used as an anti-adherent in the processing of medicines. Also, this chemical is used to bind sugar in hard candies and is a common ingredient in baby formulas. We offer this Magnesium Stearate at industry leading price to the clients.

Features:

-

Precise composition

- High effectiveness

- Purity

- Accurate pH value

Magnesium stearate, also called octadecanoic acid, magnesium salt, is a white substance which is solid at room temperature. It has the chemical formula Mg(C18H35O2)2. It is a salt containing two equivalents of stearate (the anion of stearic acid) and one magnesium cation (Mg2+). Magnesium stearate melts at about 88 oC, is not soluble in water, and is generally considered safe for human consumption at levels below 2500 mg/kg per day.

Industrial-Grade Quality Assurance

Our Magnesium Stearate is produced to meet stringent industrial standards, ensuring a consistent 99% purity for optimal performance across various applications. The granular physical form enhances its ease of integration into production processes, making it an ideal choice for manufacturers demanding reliability in their raw materials.

Versatile Applications and Usage

Magnesium Stearate is widely employed in the pharmaceutical, cosmetic, and food industries. Its primary function is as a lubricant in tablet formulation, preventing ingredients from sticking to equipment. Additionally, it helps maintain product consistency and improves manufacturing efficiency, highlighting its versatile industrial value.

Safe Storage and Extended Shelf Life

For best results, Magnesium Stearate should be stored at room temperature, away from moisture and direct sunlight. With a shelf life of 12 months, it retains its chemical integrity when handled according to recommended guidelines, ensuring reliable performance throughout its storage period.

FAQs of Magnesium Stearate:

Q: What is the main benefit of using Magnesium Stearate in industrial applications?

A: Magnesium Stearate acts as an effective lubricant and flow agent in manufacturing, particularly in pharmaceutical tablet production, where it prevents ingredients from sticking to equipment and ensures uniform consistency throughout each batch.Q: How should Magnesium Stearate be stored to maintain its shelf life?

A: The product should be stored at room temperature in a dry, cool area, away from direct sunlight and moisture. Proper storage conditions help maintain its 99% purity and extend its shelf life to up to 12 months.Q: When is Magnesium Stearate typically used during the production process?

A: Magnesium Stearate is generally added towards the end of the tablet or capsule manufacturing process, serving as a lubricant to prevent active ingredients and excipients from adhering to mixing and compression equipment.Q: Where can Magnesium Stearate be sourced from in India?

A: We are a leading exporter, manufacturer, supplier, and trader of high-purity Magnesium Stearate in India, offering reliable bulk supply to various industries domestically and overseas.Q: What makes the physical form of Magnesium Stearate suitable for industrial use?

A: Its granular physical form ensures easy handling, blending, and uniform dispersion within mixtures, making it suitable for large-scale manufacturing environments where consistency is critical.Q: Is Magnesium Stearate soluble in water, and how does this property affect its usage?

A: Yes, Magnesium Stearate is soluble in water, which facilitates its even incorporation into formulations during the manufacturing process, enhancing product quality and uniformity.Q: What industries can benefit from the use of Magnesium Stearate?

A: Industries such as pharmaceuticals, cosmetics, and food processing benefit from Magnesium Stearate owing to its lubricating, anti-adherent, and stabilizing properties, making manufacturing processes more efficient and products more consistent.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Excipients Category

Calcium Stearate

Shelf Life : 2 years

Storage : Other, Store in a cool dry place away from moisture and heat.

Physical Form : Solid

Purity(%) : 99%

Medicine Name : Calcium Stearate

Zinc Stearate

Shelf Life : 24 months

Storage : Store in a cool dry place away from direct sunlight and moisture., Other

Physical Form : Powder

Purity(%) : 98%

Medicine Name : Zinc Stearate

Sodium Starch Glycollate

Minimum Order Quantity : 100 Kilograms

Shelf Life : 12 Months

Storage : Room Temperature

Physical Form : Powder

Purity(%) : 99%

Medicine Name : Sodium Starch Glycollate

Microcrystalline Cellulose

Minimum Order Quantity : 100 Kilograms

Shelf Life : 12 Months

Storage : Room Temperature

Physical Form : Granular

Purity(%) : 99%

Medicine Name : Microcrystalline Cellulose

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS